How to Tile Baker Board -XPS Panels

Tile Backer Boards

ECOPA guides & advice

Install backer boards provide a waterproof base for placing tiles in your wet room. Working to prevent water from reaching the surfaces beneath the boards, tile backer boards allow you to build a totally waterproof installation, keeping your wet room clean and dry with ease. Installing tile backer boards is extremely simple and can be installed multiple ways, suiting a variety of different applications.

How to Install Tile Backer Boards on Timber Stud Walls

For Timber Stud Walls you can use 10 or 12mm Thermopanel Tile Backer Boards for studs at 300mm centres, or you can use 20mm Thermopanel Tile Backer Boards if the studs are at 600mm centres. Please ensure that all board edges are supported.

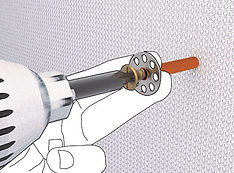

You can fix Thermopanel Tile Backer Boards to the studs using suitable screws and Thermopanel MSW36 Washers, which are made from stainless steel to prevent corrosion. The maximum spacing between fixings should be 300mm.

Following Guide Info ,there are 3 opitions for selection

Screw fixing

Tile Adhesive

Drywall Fixing

How to Install Tile Backer Boards on Solid WallsOption 1: Screw Fixing Measure the Thermopanel Tile Backer Boards and cut them to size utilising a sharp knife or saw. Wall plugs, screws and Thermopanel MSW36 Washers can be used at 300mm spacing to fix Tile Backer Boards to a solid wall.

ption 2: Tile Adhesive A 5 to 8mm trowel is used to comb flexible tile adhesive over the whole surface of the Thermopanel Tile Backer Board. Stagger the Thermopanel Tile Backer Boards in a brickwork fashion, pushing them firmly onto the wall.

Option 3: Drywall Fixing Apply Thermopanel Drywall Foam to the Thermopanel Tile Backer Board, firstly around the perimeter and then at approximately 300mm centres. For easy installation, lay the board flat with its end against the wall. Fix the Thermopanel Tile Backer Board to the studs using screws and Thermopanel MSW36 Washers. The maximum spacing between fixings should be 300mm. Allow the foam to cure for 4 to 5 minutes and then lever the board into position. Press firmly across the whole face of the board, starting at the top. Ensure the top and all edges receive as much pressure as the rest of the board.

.jpeg)

%20Thickness%20Options%203mm%2C%205mm%2C%2010mm%20Thermal%20Resistance%20R-.jpg)

Backer Board XPS Sandwitches Panels

Backer Board XPS

The innovative insulation board

it is high-performance building materials manufactured through an extrusion process. These closed-cell backing panels offer exceptional thermal resistance and compressive strength, making them ideal for wall insulation, roof thermal barriers, and ground moisture protection. As premium backing board materials, XPS foam blocks maintain stable physical properties even under extreme temperature conditions, serving as perfect insulating solutions for various construction projects.

Advantage:

1.Superior Insulation – Low thermal conductivity for excellent energy efficiency

2.High Compressive Strength – Ideal for floors, roofs, and structural support

3.Moisture & Mold Resistant – Closed-cell structure prevents water absorption

4.Lightweight & Easy to Install – Simple to cut and handle for faster construction

5.Eco-Friendly & Durable – CFC-free, long-lasting performance

6.Drip does not seepage: composite waterproof structure, 48 hours of immersion without infiltration, the end of moisture hidden trouble.

7.Ultra-strong load: vertical load-bearing ≥ 600kg / ㎡, impact resistance up to 3 times the national standard, the wall and floor general non-collapsing.

8.Second installation revolution: self-locking snap installation, without professional tools, single person 1 hour to complete 30 square meters paving.

9.Anti-corrosion and durability: 40℃~150℃ extreme environment without aging and cracking.

10.All scenes are compatible: bathroom/kitchen/basement all-round fit, compatible with tiles, rock slabs, marble and other 8 types of finishes.

More accessaries enclosed offer for installation ,please enquiry our expert ,you can get guide guide info and guide video